- Home

- Lubricants

- MWF

- Green Chemicals

- EV Fluids

- Service

- Contact Us

Current Position : homepage >>Lubricants >>Compressor & Vacuum Pump >>Compressor Cleaning Fluid >>Quick Clean Series

Current Position : homepage >>Lubricants >>Compressor & Vacuum Pump >>Compressor Cleaning Fluid >>Quick Clean Series

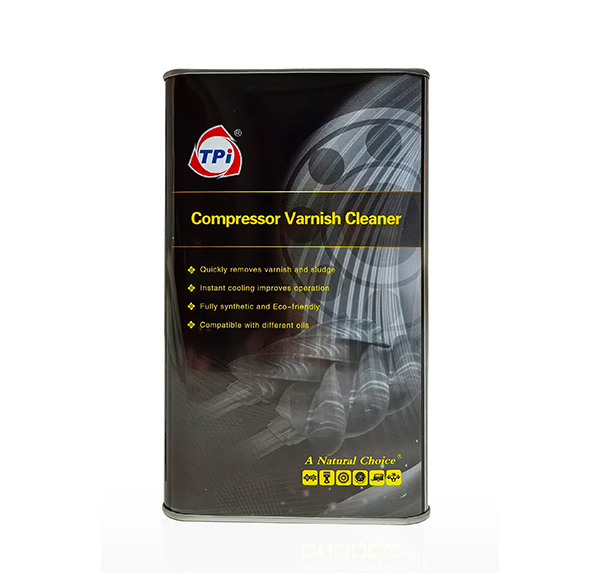

Product Overview

QUICK CLEAN series is a synthetic rapid online cleaning fluid manufactured using patented technology, designed for cleaning various circulating lubrication systems. It is particularly effective at rapidly removing sludge and carbon deposits within compressors. Using the QUICK CLEAN rapid cleaning agent allows for online operation, efficiently removing contaminants such as carbon deposits and sludge.

Product Details

Performance Advantages

● Formulated with patented technology and special components, it is fully compatible with synthetic esters, polyethers, PAO, and mineral compressor oils.

● Can be added directly online for use without disassembling the machine. It rapidly dissolves and cleans compressor sludge, varnish, and coke deposits online.

● Compared to conventional online cleaning oils on the market, it acts quickly, improving efficiency by 10-30 times, meeting requirements for rapid maintenance, cost reduction, and efficiency improvement.

● Solves problems caused by compressor head coking and oil circuit contamination, such as high temperatures and blockages, reducing operating temperature by 5-20°C and extending equipment service life.

● Dosage is flexible and controllable. The addition rate ranges from 3% to 15% based on the condition of the compressor oil circuit, ensuring cleaning effectiveness.

● Contains no components that corrode metals or seals, ensuring safe and reliable use.

Applications

Used as an online cleaning fluid to rapidly decompose and remove sludge, carbon deposits, and other impurities from the compressor head and oil circuit. It is especially suitable for compressors that have long used mineral and hydrocarbon synthetic oils. This product can also be used for cleaning hydraulic systems, heat transfer systems, gearboxes, and chain drive systems.

Usage Method

For general cleaning, add 3%-5% of the compressor oil volume. For 100 liters of compressor oil, add 3-5 liters. For long-term, stubborn coking, add 10-20% for intensive cleaning.

Before compressor maintenance and oil change, first drain part of the old oil, then add QUICK CLEAN in an equal proportion.

Start the air compressor and operate normally for 2-4 hours, then drain the old oil. To thoroughly remove the lubricant and cleaned contaminants from the machine, it is recommended to drain the oil immediately after shutdown while the machine is warm. Slightly pressurizing the system during drainage can help completely expel the old oil.

Replace the oil/air separator and oil filter.

Add the prepared new oil and start the air compressor normally.

The cleaning is complete after draining the old oil. If significant residual oil remains in the compressor, it is advised to flush with new oil or TPI system flushing oil again.

To maintain optimal compressor efficiency and lower operating temperatures, regular use of QUICK CLEAN during oil changes is recommended.